What is the process of processing coffee beans?

Each coffee processing method has its own advantages and disadvantages, depending on the characteristics of each coffee variety that people choose the appropriate processing method. The methods of processing coffee beans are carried out according to different processes, technical requirements and equipment.

To process green coffee, we will have many stages and different coffee processing methods. Each stage plays a role in determining the quality of the finished coffee beans. So what is the process of processing green coffee and what are the coffee processing methods?

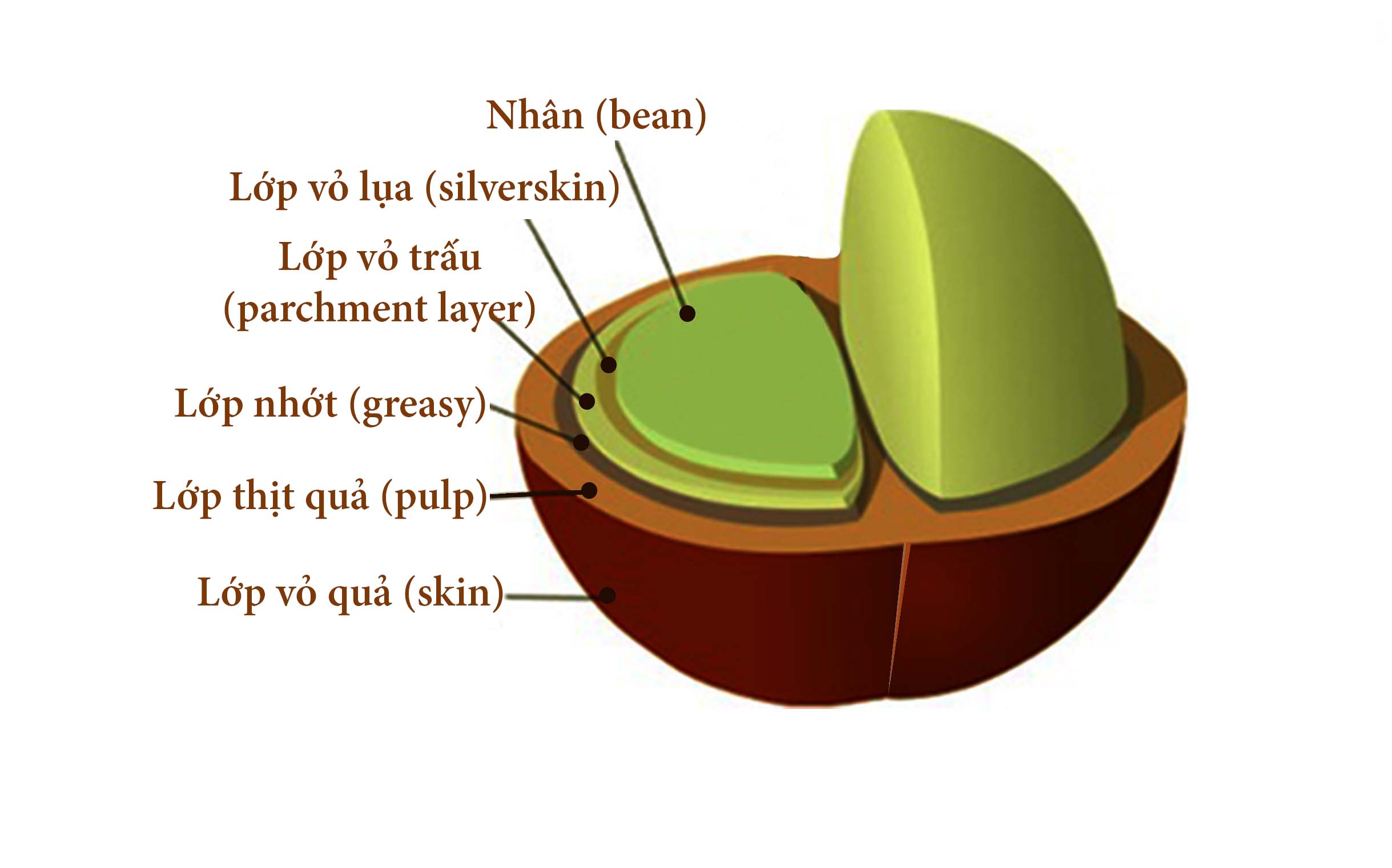

1. COFFEE BENE STRUCTURE

According to the structure from the outside to the inside, 1 coffee will have 7 components as follows

Bark

This is the outermost layer of the coffee fruit, the rind of the coffee fruit changes color during growth, from green when young to red when ripe. Some varieties of coffee are yellow or orange when ripe.

Fruit flesh

As the second layer on the outside, it has a sweet taste, contains a lot of sugar and accounts for 42 to 45% of the ripe coffee fruit weight. Eggplant meat is the favorite food of some animals such as squirrels, elephants, mink…

Viscous layer

It is an ingredient that protects coffee beans from pests and diseases when the fruit is not harvested, accounting for about 20-23% of the ripe fruit weight.

Rice husks

Coffee beans after preliminary processing will still have a hard shell, this component is retained to protect the beans from harmful agents while waiting for roasting and is removed before roasting to prevent the beans from burning.

Testa

Behind the shell is a very thin silvery-white silk layer, which is the ingredient that creates the aroma of coffee beans after preliminary processing.

Green kernel

As the most important part of the coffee fruit, it is responsible for accumulating nutrients for embryo germination. A coffee fruit usually has 2 seeds (in some cases there will be 1 or 3 beans). Green kernel has a rich chemical composition. Includes water-soluble compounds such as: caffeine, trigonelline, nicotinic acid, carbohydrates. And some proteins, minerals and water-insoluble compounds such as cellulose, lipids, etc. chemical components are considered as precursors of flavor and aroma in roasted coffee beans and coffee cups after they have been roasted. extract.

Coffee trench

Is the inner fold of the green core. Because there are many ingredients, the green coffee beans have to go through a complicated and complicated processing process. This is the new guarantee of the exact quality and taste of the coffee beans.

2. COFFEE PROCESSING METHODS

2.1. Method of processing dry coffee beans

2.1.1. What is natural drying?

Dry/ Natural/ Unwashed is a natural coffee processing method. This method uses sunlight to dry the coffee beans. The advantage of this method is that the seeds have a sweet taste, less sourness, and a strong aroma. The downside is that the quality of coffee beans is not uniform due to weather factors and long exposure time. What is the process of processing coffee beans?

2.1.2. Process of processing dry coffee

Step 1: Harvest the coffee berries.

Step 2: Remove young seeds, leaves, branches and dirt on the harvested coffee cherries.

Step 3: Sun drying for 25-30 days to reduce the moisture content of coffee beans to 12-13%.

Step 4: Dry coffee cherries are machine-milled to remove the outer skin, dry skin and produce finished coffee beans.

Step 5: Store coffee beans in a bag (sack), keep in a cool, dry place and wait until roasting.

2.2. Method of processing semi-wet coffee beans

2.2.1. What is the semi-wet coffee processing method?

The method of processing wet coffee beans (Semi-washed / Honey / Pulped Natural) is that the coffee beans are peeled and partially removed before drying / drying. This method helps coffee taste sour, plump and have a rich, rich fruit aroma. The downside, the quality of coffee beans depends greatly on the temperature of the sun and the milling technique of the preprocessor.

2.2.2. Semi-wet coffee processing process

Step 1: Harvest coffee, remove impurities.

Step 2: Scrape off the coffee skin and part of the slime layer.

Step 3: Dry or dry by machine.

Step 4: Store pre-processed coffee beans in sacks, place in a cool, dry place.

2.3 Method of processing wet coffee beans

2.3.1. What is the method of processing wet coffee beans?

The method of processing wet coffee (Full-washed / Washed / Wet) is very complex, uses many types of machines and consumes significant amounts of water, often used when processing Arabica coffee. With this method, the coffee cherries will be completely removed from the skin and flesh before being dried. Wet coffee processing method produces high quality green coffee products, delicious taste, uniform color and quality. Coffee produced by wet processing always has a higher commercial value than other methods.

2.3.2. Wet coffee processing

Step 1: Harvest and remove impurities of coffee

Step 2: Coffee berries are put into the grinder, completely cleaning the skin, flesh and mucus layer.

Step 3: Then, the coffee beans are put into a large tank to ferment with natural yeasts and additional yeast preparations, this step has the effect of completely cleaning the remaining mucus after rubbing, and at the same time help coffee beans have more acidity and aroma.

Step 4: Coffee beans after fermentation will be washed, then dried or dried, the moisture content of coffee beans is 12.5%.

Step 5: Preserve the coffee.

EPILOGUE

Each method applies different processes for processing coffee beans. This process will affect the quality and taste of the coffee beans. Therefore, experts are always careful, meticulous and follow many principles when processing coffee beans.